A SPECIAL ATOM CHRISTMAS

This year, Atom returned to celebrate Christmas with a special lunch for all collaborators. The catering service of the event was by Dolce Positivo, a work and social inclusion project which includes workers with intellectual and physical disabilities and people with social fragility.

A great occasion for both celebration and reflection, looking to the future and a new year together.

ATOM MB AND CERIM JOIN FORCES: AVANTIUM IS BORN

Atom MB and Cerim give life to a new industrial project with the aim of strengthening the offer and the international competitiveness of the two companies in the footwear machinery market.

AVANTIUM is the company, equally owned 50% by ATOM and 50% by Cerim, in which the industrial contents of Cerim and MB will converge. A synergy that will make it possible to optimize customer service and strengthen the international presence, as well as guaranteeing the full protection of all human resources.

The goal is to strengthen the experiences of individual brands and to jointly develop the production and distribution network with an enlarged and integrated catalog of products.

A consolidation operation in which the shareholders have decided to invest without resorting to external finance, agreeing on an industrial plan that starts from a strong structural choice: unite to grow.

Technology and excellence: Atom is among the SME Champions of made in Italy

For 2022, Atom is confirmed among the 1,000 top performer companies of Italian economy, awarded for their performance and ability to overcome the health emergency and face the international economic and political crisis to plan the next relaunch.

The research carried out by the ItalyPost Study Center in collaboration with “L’Economia”, the financial weekly publication of the Corriere della Sera, has in fact confirmed the Vigevanese company among the Champions companies of our country, which over the years has developed cutting-edge technology applied to many production sectors, becoming a world leader in the production of systems for cutting flexible and semi-rigid materials. A success which is due to a solid business model and continuous technological innovation.

The research has identified 800 companies situated in the national territory with a turnover ranging between € 20 and € 120 million, as well as 200 top companies with a turnover between € 120 and € 500 million, which were selected based on the careful analysis of the available financial statements of the last six years. (2014-2020 period) and a series of strict corporate and economic criteria (such as Cagr, EBITDA, Rating and NFP).

The digital transformation of production processes

Limiting the movement of goods and people with the creation of “digital infrastructures”, in which data is exchanged and analysed in all operational phases: this is the goal that has guided the development of the new ATOM products.

From the design phase to its delivery to the final Customer, the whole process can be digitized, becoming faster and more efficient.

Virtual prototyping, production chain management, CADCAM Engineering, production control, automation and e-commerce: these are the phases of the process that can be connected through a new digital infrastructure.

For each of these areas, ATOM is able to offer software and hardware tools, single machines or complex automated systems, ready to be integrated with existing production lines, using the most popular standards for interconnection and data exchange.

More effective, faster and more productive systems, able to be remotely controlled and to exchange information even between factories which are physically located in different parts of the world: a new way for industrial production takes shape thanks to ATOM technology.

ATOM Germany, the Open House event is a great success

The open event organized by ATOM Germany obtained an excellent feedback: the aim was to present all the latest cutting systems for different materials.

ATOM MB, AUTOMATION AND DIGITAL STRENGTHEN THE HISTORICAL KNOW HOW OF THE BRAND

Footwear

Atom MB enriches its offer with new types of machinery and with solutions for the automation of the production process.

Following the integration within the corporate structure of Atom and leveraging the industrial and financial strength of the group, Atom MB has in fact strengthened its research capacity and competitiveness at an international level, thanks to the support of a worldwide network that today includes direct branches in 10 countries and a widespread technical assistance system.

The new Atom MB products integrate the consolidated technological offer solutions of automation and remote control, allowing a greater efficiency and precision.

The most tangible result of this evolution is RAMS (Robot Assisted Manufacturing System), an integrated system for the processing of footwear, which can include one or more operations within an automated line. Extremely flexible, this solution is now operational in various production sites that work for the major luxury brands.

The new hydraulic toe laster Sincron HR completes the Sincron series: intended for large series production, it has been developed in cooperation with Reces, a historic company with 60 years of experience in the industry.

With a view to increased efficiency but also greener processes, the new Sincron TSX is also born: the only machine in the world of its kind, the Sincron TSX has achieved 100% of clean energy drive, eliminating the hydraulic oil circuit and increasing speed and precision; it is also characterized by new generation actuators that are faster, more reliable, with lower energy consumption and equipped with IoT functionality and predictive maintenance.

For the cementing phase, the most updated solution is the CD15 VRX, robotic cementing machine capable of processing any type of sole, even the most complex.

The new Atom MB proposals combine consolidated know-how with the latest technologies for automation and digitalization of processes, offering a perfect solution to build increasingly efficient, smart and interconnected productions.

ATOM is once again “CHAMPION ENTERPRISE”

ATOM is once again “CHAMPION ENTERPRISE”

For the 3rd year in a row, ATOM Group is one of the 1000 Italian enterprises with the best business performance between 2013 and 2019 and is re-confirmed as “IMPRESA CHAMPION 2020”.

The research was carried out by the Study Centre of ItalyPost – in collaboration with L’Economia of Corriere della Sera – and it takes in consideration the highest year-to-year above-average growth of Italian companies with revenues between 20 and 120 million euros, as well as between 120 and 500 million euros.

The following economic and financial criteria were used to evaluate the companies:

- CAGR (compound annual growth rate) greater or equal to 4.22% between 2013 and 2019;

- Average EBITDA in the last three financial years greater or equal to 8.72%

- PFN/EBITDA ratio

- Rating

Given the current economic context, the result represents an important trust signal in a quick restart of the Country and confirms the success of Atom’s strategy, based on solidity but always attentive to innovation: the company is in fact preparing to achieve new ambitious goals especially in terms of investments in automation and digitalization of processes.

ATOM DONATES AN INTENSIVE CARE UNIT TO VIGEVANO CIVIL HOSPITAL

Atom Group companies contributed € 100.000 to Civil Hospital in Vigevano for the acquisition of an intensive care unit: a concrete act for the city and the territory, as a sign of closeness and gratitude to all the staff which is strongly facing this health emergency. This donation aims at celebrating the memory of Emiliano Cantella, one of Atom founding members, and supporting the difficult daily struggle of the team working in the Intensive Care Unit of Civil Hospital in Vigevano.

SAMUPLAST

6-8 FEB 2020 PORDENONE (ITALY)

Foam - Rubber and plastics

We will be at SAMUPLAST Pordenone

From 6 to 8 Feb 2020.

Best Wishes from Atom Group

Best Wishes from Atom Group

ATOM AT K-MESSE

Rubber and plastics

The K fair of Düsseldorf – the leading event for plastics and rubber – ended on 23 October.

Atom achieved great success thanks to its cutting-edge and sophisticated products. Special attention was paid to the new combined cutting and milling system equipped with automatic tool change solution (FlashCut Twins EMHD.)

By leveraging the versatility and modularity of the products in its range, Atom will present the FlashCut TWINS EMHD model, which is able to cut foam materials with a thickness up to 130 mm thanks to the new silenced pneumatic spindle.

The cutting tool can be combined with the milling tool (5 KW electric motor with inverter which operates the spindle up to 30,000 rpm) to perform any kind of insert at different depths in the material.

Moreover, it is also possible to perform the automatic detection of the height of the blade tool as well as of the milling tools: the operation is carried out directly by the control software upon each replacement.

Another important element is the sector vacuum chamber, where the automatic opening/closure of the sectors is performed by the control software depending on the position of the cutting geometries put on the work surface. The placement software supplied with the machine includes both the interactive and automatic mode.

Modern and sophisticated, it is equipped with a large control console, industrial touch-screen monitor and a safety laser scanner capable of automatically detecting the presence of any person moving near the working area.

The high-brightness projector that reflects in 1: 1 scale the cutting paths on the material placed on the working surface is optional.

OPEN HOUSE

Atom will be at Open House in Cincinnati, Ohio from Monday November 11th through Friday November 15th. This is an excellent opportunity to witness live demonstrations for industry leading CNC digital knife cutting systems, die cutting presses (CNC / Flat-Bed / Rotary), laser cutting.

Find out more at this link: MSC OPEN HOUSE

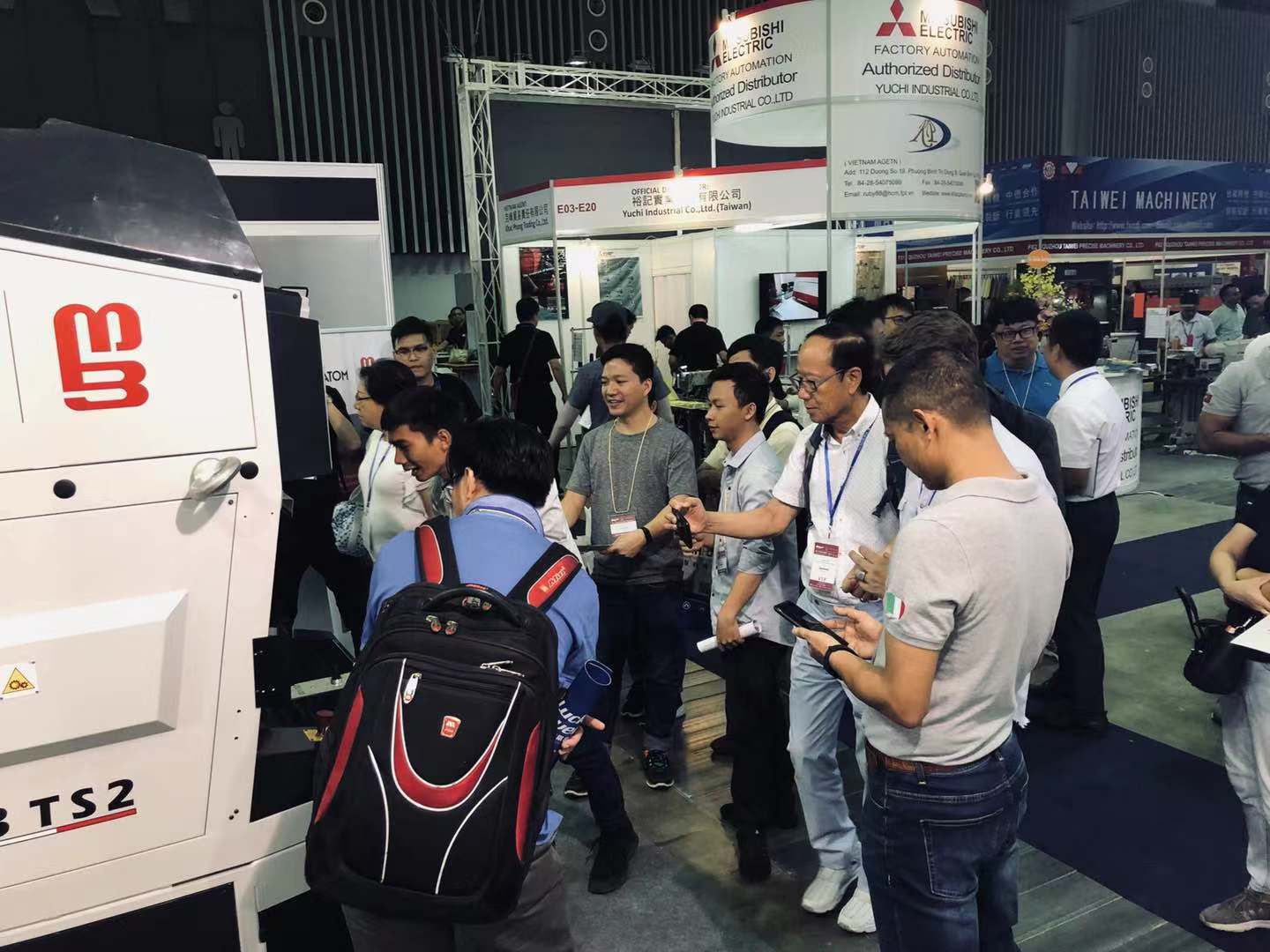

SHOES AND LEATHER VIETNAM 2019

Footwear - Leathergoods

The 21st international Shoes and Leather Vietnam, one of the most famous one-stop platform dedicated to footwear and leather goods in Asian market, was ended on Friday.

The fair attracted 750 exhibitors distributed on 20.000 mq exhibition area and 15.000 visitors.

The Atom group’s offer has been a great success: Atom, Atom MB, Shoemaster and Main Group have showed innovative solutions for all the footwear production stages, from design to the cutting of materials, including the moulding of soles and the assembly of the item.

ATOM CUTTING SYSTEMS CERTIFIED BY TUV SÜD

A leading certification body at global scale

Atom is about to earn the prestigious TUV SÜD certification for its full range of products. This important recognition is issued by a leading certification body at global scale, which assesses the quality and safety of the machines produced.

Currently, the TUV SÜD certification has been granted to FlashCut Speedy 1660, FlashCut Speedy 2160 and FlashCut Speedy 2660, able to ensure the utmost productivity and efficiency, thus proving to be particularly suitable for the use in the footwear and leather industry.

The TUV SÜD certification has also been issued for FlashCut Fashion 26B All-in-One and FlashCut Fashion 31B All-In-One, which combine processes of acquisition, automatic nesting and cutting in a single machine. Operating in continuous workflow, they reduce the working time and allow all the production steps to be performed by only one operator.

These products were able to meet the strictest regulatory and certification requirements, having passed the various compliance tests in line with Atom’s commitment to offer its customers the utmost security and reliability. The TUV SÜD certification is a further proof of Atom’s excellent products, resulting from the attention paid to every detail that has always characterized the company activity.

ATOM GROUP IN CHINA

The best footwear technologies unveiled in Guangzhou

Footwear - Leathergoods

Atom Group has returned to Guangzhou, China, to take part in the Shoes & Leather event – the most important fair in the industry which took place from 30 May to 1 June – where it presented the best footwear production solutions.

In particular, at its own stand, Atom unveiled the Atom knife and die-cutting machines, including FlashCut Speedy 1660 and FlashCut Speedy 2660, which radically changed the previous concept of cutting tables which were regarded as mere sampling and small production tools, Fashion 31B All-in-One with the largest working surface in the Atom range, FlashCut Twins 3015, as well as FlashCut Easy 888 and FlashCut Easy 888 L 30, characterised by great precision and speed.

The Atom MB area, conversely, showcased the footwear assembly machines, including CD3 TS2, which can simultaneously carry out multiple processes, the Mark 2 TSI and Mark 3 TSI heel seat and sides lasting machines and, eventually, the cutting-edge Sincron TS and Sincron 4 Pulling over lasting machines, provided with 11 pincers at pneumatic functioning with microprocessor control.

Eventually, Main Group presented its sole moulding solutions and Shoemaster its CAD-CAM systems.

Atom Group still establishes itself as the only point of reference for all the footwear production process steps thanks to its complete range of design, product engineering and automated process technologies. Thus Atom strengthens its position in China, one of the strategic markets for the Group, where it is represented by Atom China, Atom Guangzhou e MGT Shanghai as a production hub for the leading footwear industry, especially in the sports sector.

Next month, Atom Group will globally take part in Shoes & Leather Vietnam, scheduled from 11 to 13 July in Ho Chi Minh City.

ATOM GROUP IS ON LINKEDIN

What are you waiting to follow?

From today, Atom Group is also on the world’s largest professional network, LinkedIn.

Add us to your companies to follow to stay updated on all our latest news, products, events and future projects.

Follow us here

SIMAC TANNING TECH: WHAT YOU MISSED OUT

Fiera Milano Rho 20/22 February 2018

Automotive interiors - Fabrics - Footwear - Furniture - Leathergoods

A wide range of technological solutions for the cut of leather and synthetic materials: at Simac Tanning Tech, Atom has presented some solutions for several production needs, from the smallest machines ideal for prototyping, to the ones dedicated to small and medium production, to the completely automated high production systems.

The main features of all production “made by Atom” are the quality of the production and the cutting-edge technology. Atom offers state-of-the-art solutions for materials cutting, such as the cutting table FlashCut Fashion 31B All-in-One, equipped with the largest working area of the Atom range to acquire, nest and automatic cut in continuous hides of any size, and the cutting table FlashCut Speedy 1660 BP UP, granting high productivity and cutting precision.

Take a look at the video

ATOM GERMANY GRAND OPENING

Atom Group has opened its new headquarters in Germany

Atom Group keeps to the path of renewal of its offices across the world: after the renovation of its headquarters in Vigevano, now it’s the turn of the new office in Germany, officially opened last 12th of May in Pirmasens, at Gewerbepark Husterhöhe, Massachusetts Avenue 28, at the presence of Atom Group top management.

After 12 years new offices, new meeting rooms and new spaces for Atom machines has been created. A place that aim to be more than just the new German branch office: the goal of the new project, in fact, is to create a workplace that is symbolic of the Atom entity, now world-leading company and example of innovation and research worldwide.

To celebrate the new office opening, the exhibition “Atom: The Cutting Factory”, come in Germany last April in the occasion on Kreativvitti, the first and most important German exhibition for cultural and creative industries, will take place until 28th of May at Der Rheinberger, Fröhnstrasse 8, in Pirmasens, adding another step to its journey.

For more info: info@atom-germany.com

ATOM GROUP’S FAMILY DINNER

Atom Group celebrates his first 70 years of activity during Christmas time

Last 23rd of December, Atom Group dedicated a gala evening to Atom, Main Group, Atom MB and Shoemaster staff in the beautiful setting of Castello Sforzesco’s Cavallerizza room, in Vigevano. The dinner, preceded by a guided visit to the exhibition “Atom: The Cutting Factory”, has been a chance to celebrate Atom 70 year activity travelling across past and present of the Group.

“ATOM: THE CUTTING FACTORY": AN EXHIBITION TO CELEBRATE 70 YEARS

Atom celebrates its first 70 years of activity with ”Atom: The Cutting Factory”, a design exhibition open to the public that will take place from the 11th to the 30th November 2016 at “La Triennale di Milano”.

12 designers through 12 works of design will highlight the potential of Atom technology: all the projects explore the creating process of the product and look at the materials and interaction between them, all within a scenario that combines art, fashion, design and technology as well as aesthetics, to show the comprehensive production potential of Atom systems and solutions. The result will be an exhibition of works of design made with the several materials Atom technology can cut.

The goal is to give a symbolic value to the expertise and the history of Atom, by showing the potential of Atom cutting systems. The installation, indeed, highlights the multi-sectorial nature, versatility and wide soul of Atom. During the 20-day exhibition, an assorted audience can learn about the reality of Atom, through multi-media presentations showing the history and traditional production of Atom. In addition to this, videos will show the birth of concepts and implementation processes of the varied individual projects completed by each designer.

Led by Giulio Iacchetti and Francesca Molteni, curators of the exhibition, the 12 designers and design studios involved are: 4P1B, Federico Angi, Alessandra Baldereschi, Denise Bonapace, Agustina Bottoni, JoeVelluto, Francesca Lanzavecchia, Chiara Moreschi, Lorenzo Palmeri, Sovrappensiero, Vittorio Venezia.

ATOM MB IS BORN

THE NEW COMPANY ARISES FROM THE SYNERGY BETWEEN ATOM GROUP AND MOLINA E BIANCHI

The synergy between ATOM Group and Molina e Bianchi has given birth to ATOM MB, the new company of ATOM Group.

In order to enhance and complete its global strategy, ATOM has chosen to complement its product line with a major business in the footwear industry, the shoe lasting technology.

This move is part of a growth strategy, that ATOM has been carrying on for a long time to look ahead to the future with a cutting-edge approach. The past is not forgotten, but a step further has been taken to reinforce ATOM presence on the international scenario.

Thanks to the contribution of ATOM LAB, the research and innovation unit of the group, ATOM will further improve the already started route of research for advanced procedures in the footwear sector, integrating the know-how of shoe bottom processing, belonging to Molina e Bianchi, with the innovation in method and product, synonymous of ATOM. A further tile has been placed to reinforce ATOM Group leadership in the worldwide market.